Some Of Roar Solutions

( Area 0, 1, or 2). This variation will also affect the resourcing demands for work prep work. When Great deals are specified, you can create tasting strategies based on the example size of each Whole lot, which refers to the variety of arbitrary devices products to be evaluated. To figure out the required sample size, two elements require to be reviewed: the size of the Great deal and the classification of assessment, which shows the level of effort that must be applied( lowered, typical, or raised )to the evaluation of the Whole lot. By combining the classification of examination with the Great deal dimension, you can then develop the ideal rejection requirements for an example, suggesting the allowable number of faulty items located within that sample. For more information on this procedure, please describe the Power Institute Standards. The IEC 60079 standard suggests that the maximum period in between assessments should not go beyond 3 years. EEHA assessments will certainly additionally be carried out outside of RBI projects as component of set up maintenance and devices overhauls or fixings. These examinations can be credited towards the RBI sample sizes within the influenced Lots. EEHA examinations are conducted to identify faults in electrical tools. A weighted scoring system is vital, as a single tool may have several mistakes, each with varying degrees of ignition risk. If the combined score of both assessments is much less than two times the mistake rating, the Great deal is considered appropriate. If the Great deal is still thought about unacceptable, it has to go through a complete evaluation or validation, which might activate stricter inspection methods. Accepted Whole lot: The reasons for any type of mistakes are recognized. If a typical failure setting is discovered, added devices may require maintenance. Mistakes are categorized by intensity( Safety and security, Stability, House cleaning ), making certain that urgent problems are assessed and dealt with without delay to alleviate any impact on safety or operations. The EEHA database need to track and tape the lifecycle of faults together with the restorative activities taken. Implementing a robust Risk-Based Assessment( RBI )strategy is essential for making sure conformity and safety and security in handling Electrical Devices in Hazardous Areas( EEHA). Automated Mistake Rating and Lifecycle Administration: Effortlessly manage faults and track their lifecycle to enhance examination precision. The intro of this support for risk-based inspection even more strengthens Inspectivity's setting as a best-in-class remedy for regulatory conformity, along with for any type of asset-centric assessment usage instance. If you want finding out more, we welcome you to request a demo and discover how our option can transform your EEHA management procedures.

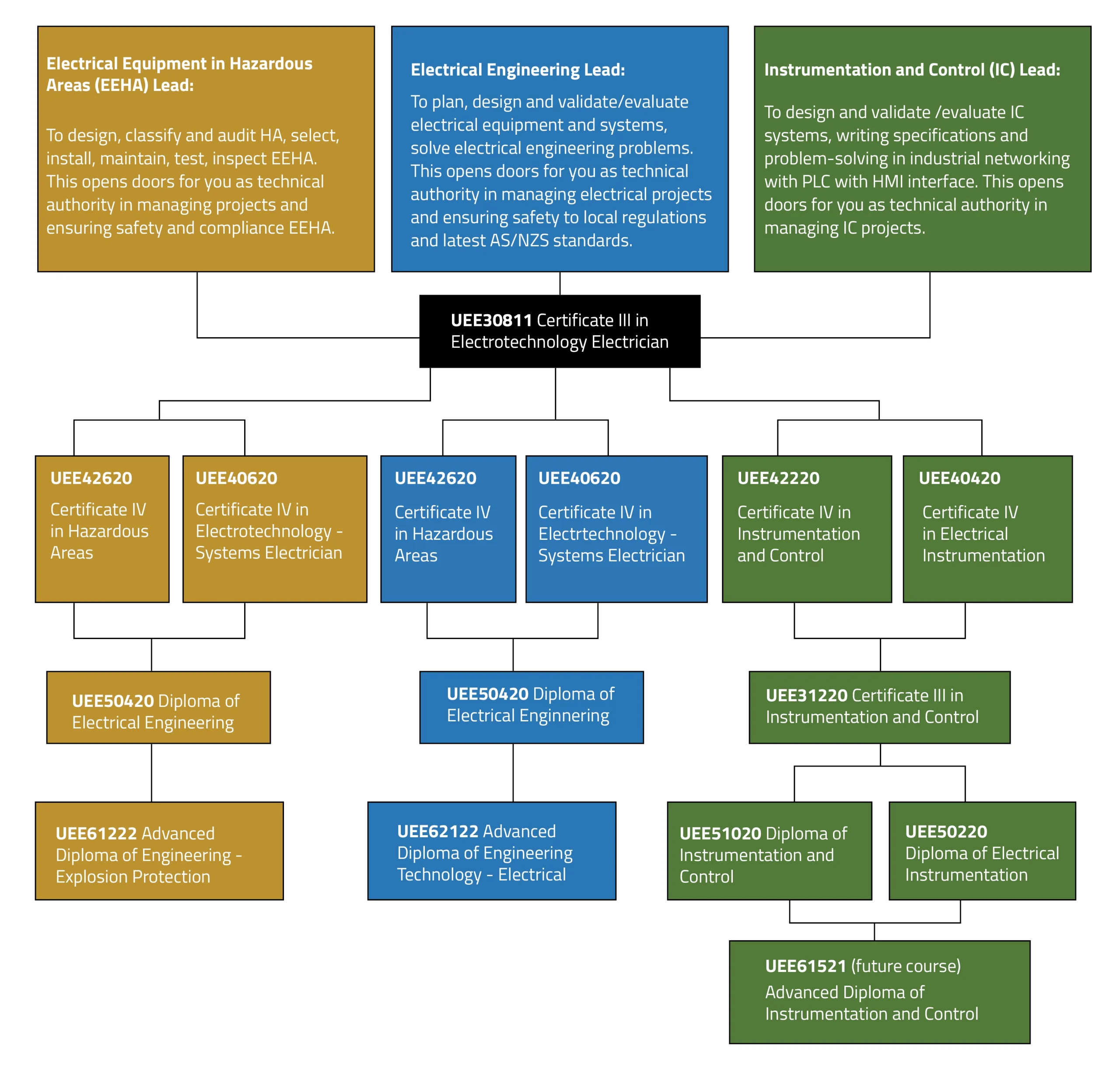

With over 10 years of consolidated Ex-spouse experience (IECEx/ATEX, EEHA), Saipex began to promote the significance of skills of all personnel involved in the Hazardous Area area in 2019. In 2021, our collaboration with IndEx and Tech Skill International (TSI) noted a landmark in the Saipex road to proceed Ex lover enhancement.

Facts About Roar Solutions Uncovered

In regards to explosive danger, a hazardous location is an environment in which an explosive atmosphere exists (or might be expected to be present) in quantities that call for unique safety measures for the building, installment and usage of devices. In this write-up we explore the challenges dealt with in the office, the threat control steps, and the needed proficiencies to function safely.

These materials can, in particular conditions, create eruptive ambiences and these can have significant and unfortunate consequences. Most of us are acquainted with the fire triangular remove any kind of one of the 3 components and the fire can not happen, but what does this mean in the context of unsafe locations?

This is then verified with evaluation and testing and is preserved throughout the life of the installation by employing the correct upkeep methods, supplemented by routine inspection. When all these actions are taken, they need to also be documented. The verification dossier includes info such as the dangerous area category drawing, producers' documentation, devices qualification, style illustrations and estimations, evaluation documents, and records of an individual's competency and continuing professional growth (CPD), such as using ECA's eCOMS software.

A Biased View of Roar Solutions

It is vital that trainees recognize and have a comprehensive understanding as to exactly what constitutes an unsafe area. The trainee must additionally recognize why training is necessary before trying to tackle job or specifying equipment into an unsafe location. These areas are additionally understood as classified locations and are defined as areas which have a high possibility of an explosion due to the possible presence of flammable gases, vapors, cleans and so on.

Industries which contain dangerous areas are currently requiring that electrical employees that are specifying or operating in these locations need to have an unsafe location credentials that regards them qualified. Jobs in these industries are extremely rewarding so you require to be prepared. To fulfill this need for the market, nationally acknowledged training in Certificate IV in Dangerous location Electric and EEHA training on the development of experienced professionals.

Roar Solutions for Dummies

Tech Skills Australia is a Registered Training Organization giving you with one of the most budget-friendly and quickest way in getting your credentials - Roar Solutions. Our instructors are sector qualified and have a number of years of procedure experience. Our courses have actually helped hundreds of people from corporate supervisors to everyday employees in acquiring a solid hold on this not so challenging however high risk training

The training also includes identifying the hazardous areas, resources of explosion and the residential properties of dangerous materials along with the responsibilities and functions of all events, policies, systems, standards and practice codes linked to harmful areas. We supply instrumentation and hazardous area services that remain in conformity to newest AS/NZS and worldwide industry criteria.

Comments on “All about Roar Solutions”